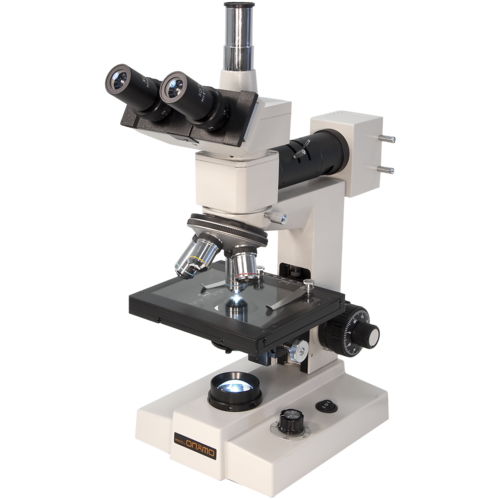

About Metallurgical Trinocular Microscope

Heavy horse shoe base and body with coarse and fine motion system triple revolving nose piece and a 150mm graduated round stage with clip. Upper plate having rotary and centering adjustment. Provided with condenser set NA1.25 movable through rack-n-pinion. Polarizer rotating and graduated to 360 degree. Analyzer and Bertrand lens is provided in a slide which can be swing in and out of themicroscope tube. Microscope tube for conoscopy observation and DIN standard compensator slot at 45 degree accommodating first circular Red sensitive Gypsumplate and 1/4th wave length retarding plate. Plano-concave reflector has been provided for light. Supplied with following optical combinations.Packed in wooden Box.

Huygenianeyepieces: P-5x with cross line

P-10xwith ocular micrometer

Achromatic objectives: P-5x, P-10x & P-40/45x (SL)

Specifications Same as model BTM 413 butprovided with Trinocular Head with 45 deg. Inclined Binocular observation andStraight tube for Photomicrography

Advanced Optical PerformanceThis microscope is equipped with achromatic objectives (5x, 10x, 40x) and anti-reflection coated glass, ensuring clear and high-contrast images. The finite or infinite optical system (model dependent) and wide field eyepieces enable precise metallurgical analysis, while Kohler illumination with adjustable intensity provides uniform, glare-free lighting for intricate observations.

Ergonomic and Sturdy DesignFeaturing a sturdy, vibration-damping cast metal base and a large rectangular mechanical stage, the microscope ensures stability during prolonged use. The trinocular head is inclined at 30 and rotatable 360, offering comfortable viewing angles and convenient simultaneous camera attachment for seamless workflow integration.

Flexible Usage and ImagingSuitable for both manual and digital analysis, this microscope's trinocular port accommodates various digital cameras, supporting high-resolution stills and videos. Optional LED illumination and polarizer/analyzer attachments allow adaptation for advanced metallurgical and material science applications, making it an indispensable tool in research, education, and industry.

FAQ's of Metallurgical Trinocular Microscope:

Q: How can the trinocular port be used for digital imaging or documentation?

A: The trinocular port allows you to attach a compatible digital camera or imaging system for simultaneous live observation and image capturing. This enables you to document microstructures, save high-resolution still images, and record videos directly from the microscope. Camera adapters supporting resolutions up to 24MP are compatible, and images can be stored in formats such as jpg or bmp depending on the camera model.

Q: What is the ideal environment to use the Metallurgical Trinocular Microscope?

A: This microscope is best used in laboratories, research centers, educational institutions, or industrial quality control settings where metallurgical, semiconductor, or material analysis is required. The heavy-duty, vibration-damping cast metal base ensures stable observation on most laboratory benches. Proper ventilation and dust-free conditions help maintain its precision and optical integrity.

Q: When should the polarizer/analyzer attachment be used?

A: The optional polarizer/analyzer attachment is ideal for advanced metallurgical studies where analyzing grain structures, coatings, or polarized light effects is necessary. Use it when enhanced contrast or detection of specific optical properties in metals and materials is required. It can be added as needed without altering the core microscope functions.

Q: Where can I adjust the stage and what is its movement range?

A: The X-Y double layer mechanical stage is located beneath the objectives and is maneuvered using the coaxial mechanical controls. It provides precise movements over a range of 75x50 mm, with graduations in microns for detailed sample positioning. This ensures accurate navigation and measurement of metallurgical specimens.

Q: What is the process of focusing and what range of adjustment is available?

A: Focusing is achieved via coaxial coarse and fine focus knobs. The stage offers a coarse adjustment range of about 30 mm for rapid focusing and a fine adjustment range of 2 mm, with precision up to 0.002 mm. This dual adjustment system allows you to locate and sharp-focus features at magnifications up to 1200x.

Q: How does the microscope benefit metallurgical analysis?

A: The microscope provides clear reflected light imaging, crucial for examining surface features and microstructures of metals and alloys without needing sample transparency. Its ergonomic design, high-resolution optics, and compatibility with digital cameras streamline analysis, documentation, and reporting, improving productivity and accuracy in metallurgical research and quality control.